About

Objective and claim of SIMPLI-DEMO

The Project

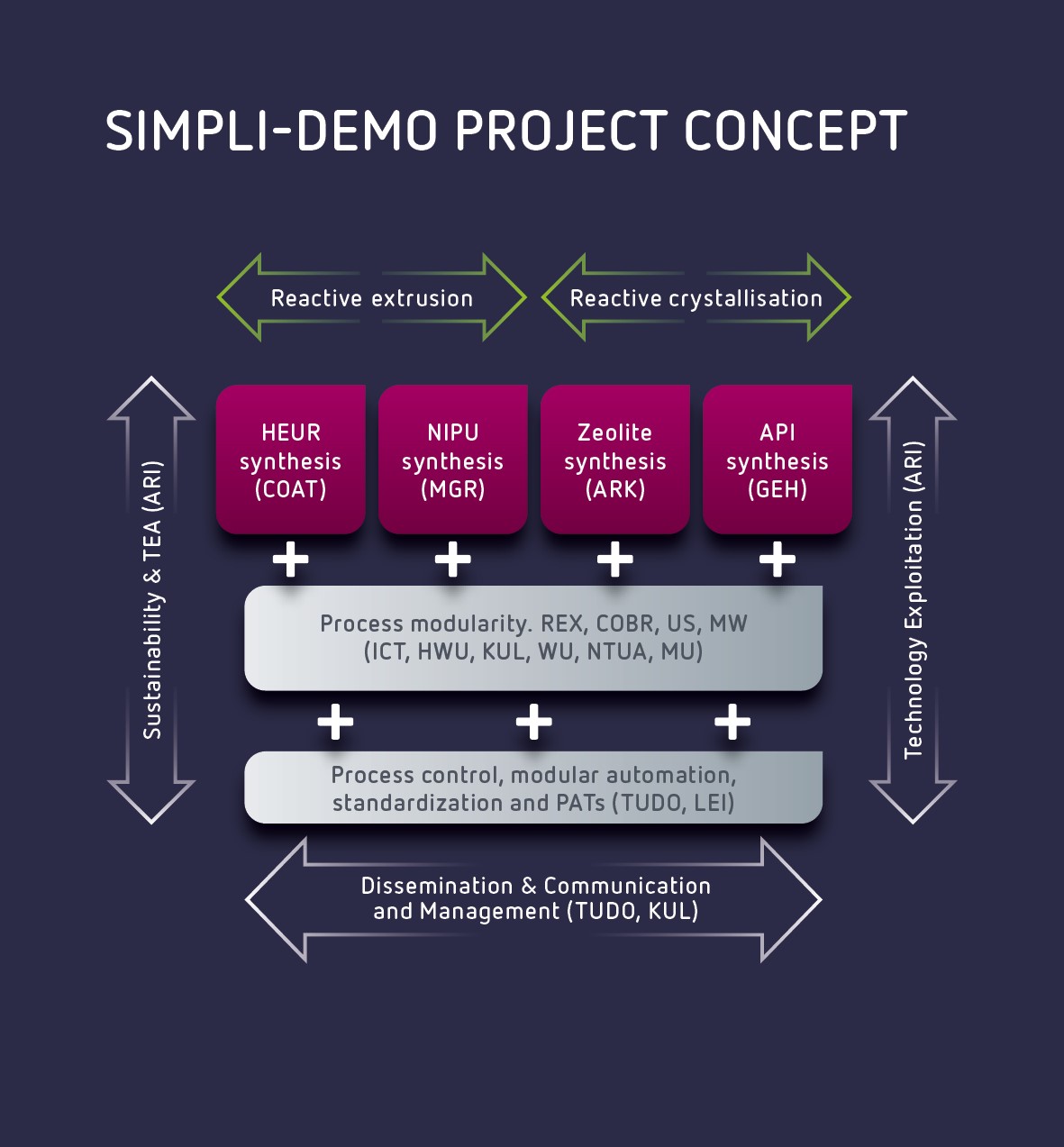

SIMPLI-DEMO – the Demonstration of Sonication and Microwave Processing of essential chemicals project – aims at strengthening the chemical process industry and in particular the specialty chemicals and pharmaceuticals industries in its capacity to produce materials and chemicals in a sustainable and competitive way.

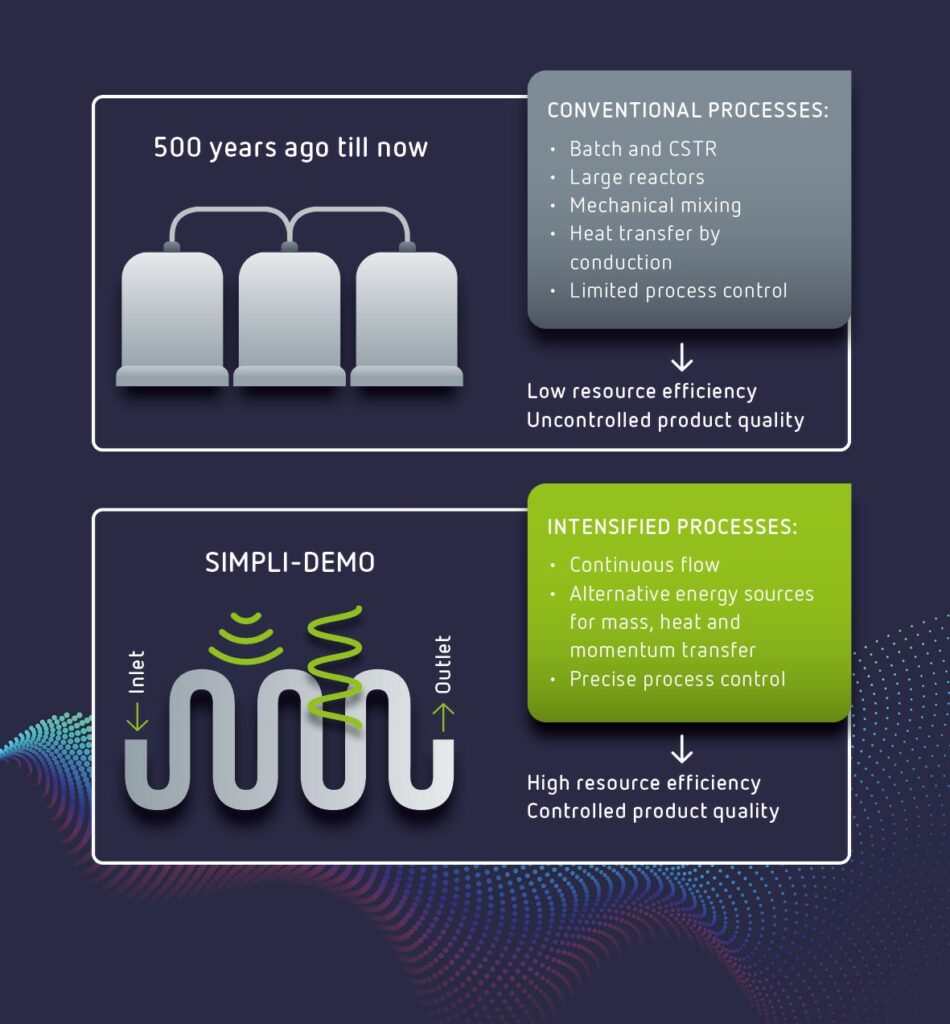

This contribution is made by moving from batch to continuous and modular production with flexibility being ensured by the application of alternative energy forms. Currently, the conventional technologies in the specialty and pharma sector tend to be batch-type, combined with mechanical mixing and conduction-based heat transfer, inherently leading to poor process control. SIMPLI-DEMO’s vision is that of intensified processes, where alternative energy sources enable continuous and modular technologies to achieve localized actuation of multiphase, flow reactors for the purpose of high-value product synthesis.

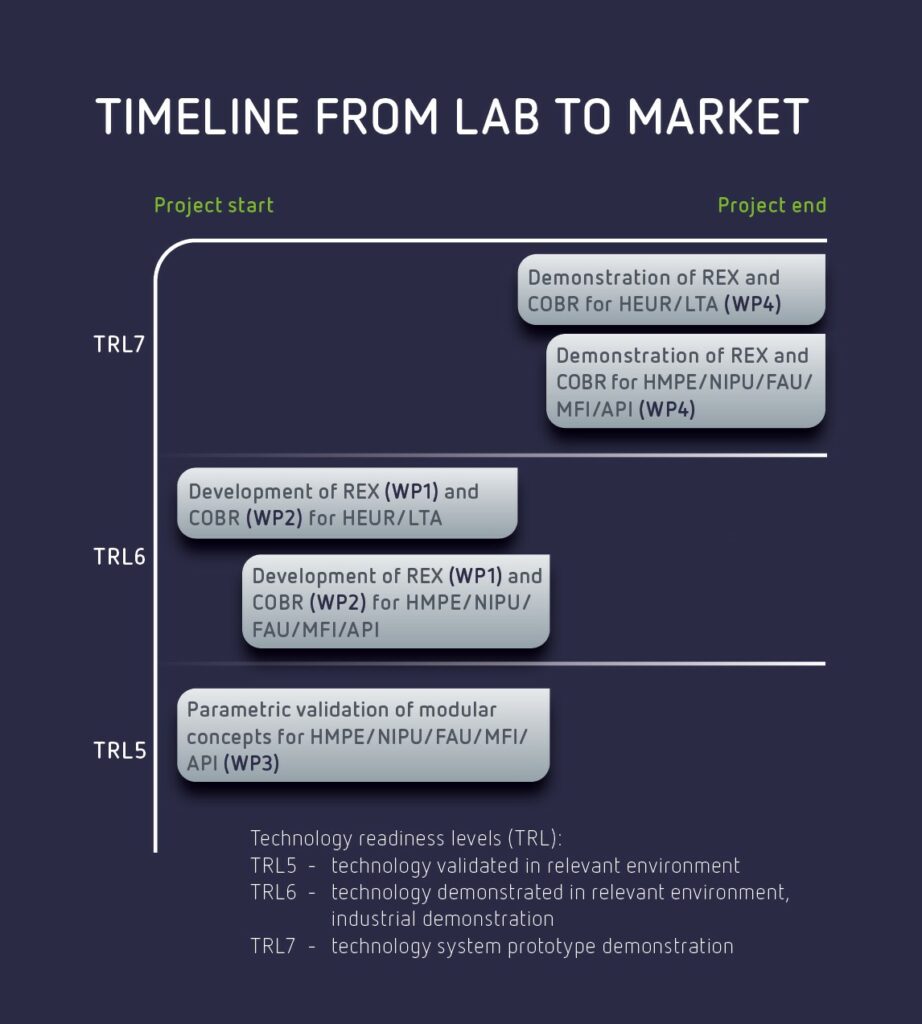

SIMPLI-DEMO focuses on the synthesis of specialty polymers and particles for use in a wide variety of every-day-use products, e.g. insulation, paints and coatings, plastics, catalysts, as well as health applications, which are important domains in the chemical industry today and into the future. Therefore, SIMPLI-DEMO advances the technology readiness level (TRL) of modular flow technology for multiphase streams involving suspensions or viscous products from TRL5 (validation in relevant environment) to TRL7 (industrial system demonstration).

The consortium is composed of 13 partner instiutions. It consists of four end user chemical companies, two technology suppliers (ultrasound and microwave technology), five universities and research institutions (process control & automation, reactive extrusion, oscillatory flow, ultrasound, microwaves), one SME experienced in modular automation and another SME experienced in sustainability assessment and exploitation.

Specific goals of the project

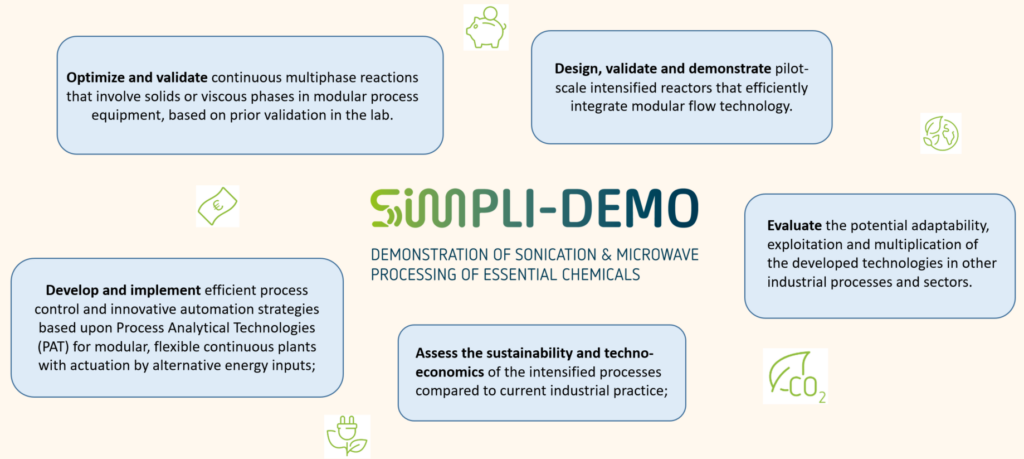

SIMPLI-DEMO’s ambition is to present the first pilot-scale system prototype demonstration for the long-term uninterrupted modular flow operation of solids-laden and viscous-phase containing liquid process streams allowing for decentralized production. We want to achieve this by combining continuous flow equipment (REX, COBR) with the alternative energy forms of ultrasound and microwaves as process enablers for the transition from batch to continuous.

SIMPLI-DEMO sets itself these ambitious goals

Work plan

The consortium has agreed on a 48-months work plan for the successful analysis, research, design, deployment, operation and evaluation of the SIMPLI-DEMO results. The Work Plan is divided in 7 Work Packages, which will be implemented in five parallel time blocks coordinated with one another.

The focus is on three technical-scientific work complexes:

1. Development of modular systems (WP 1 and WP2)

2. Parametric validation for flexible modular operation (WP 3)

3. Demonstration of the flexible modular production systems in industrial environment (WP 4)

Work packages

Innovation

The results of this project will revolutionize the way the chemical industry currently approaches the process intensification of complex multiphase processes, by overcoming the technical barriers hampering continuous flow processing. No scale-up of this extent and breadth in the field of ultrasound- and microwave-assisted continuous chemical processes has been validated and demonstrated so far.

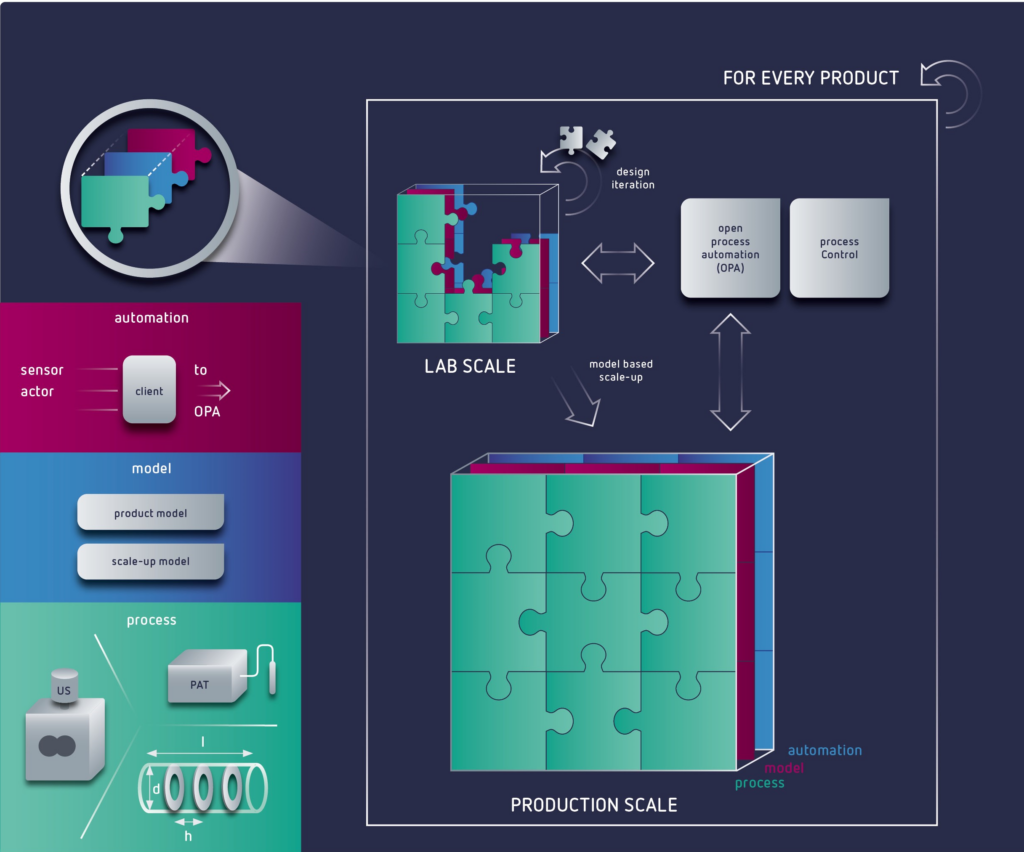

As an integral part of SIMPLI-DEMO’s general view on scale-up, an innovative modular automation approach is followed in this project. The Modular Type Package (MTP) concept describes the module interfaces and functions needed for process control and for the digital integration of encapsulated equipment modules in higher-level control systems. A controller and the basic automation functionality of a modular equipment can be easily integrated into a heterogenous, vendor-independent system environment.

Within the automation engineering, the basic automation of a module can be implemented as a black box but offering service-oriented interfaces to higher-level control systems. The higher-level control systems orchestrate the modular plant units by coordinating and invoking the services provided by each module. Overall, the MTP concept paves the way of future-oriented open and flexible service-based system architectures for process control.

Technical progress in SIMPLI-DEMO

The project follows an integrated approach along the targeted technology readiness level (TRL). The levels are a method for estimating the maturity of technologies during the acquisition phase of a program. TRLs enable consistent and uniform discussions of technical maturity across different types of technology.

The project starts with a dual approach. On the one hand, HEUR and zeolite A (LTA) synthesis in REX and COBR is developed (TRL6). this process is based on the experience of the predecessor project SIMPLIFY, which was also coordinated by the research group Process Engineering for Sustainable Systems of the KU Leuven.

On the other hand parametric validation is performed for products that start at lower TRL (HMPE and NIPU, FAU- and MFI-type zeolites, API). Once REX and COBR are developed for HEUR and LTA, they can be demonstrated in the industrial environment (TRL7), while the obtained expertise and the available equipment allow us to develop, adapt and demonstrate REX and COBR for HMPE, NIPU, FAU, MFI and API.