Process control and automation in modular systems

In our project, new approaches of automation technology concepts for modular plants are developed for our core technologies (REX and COBR).

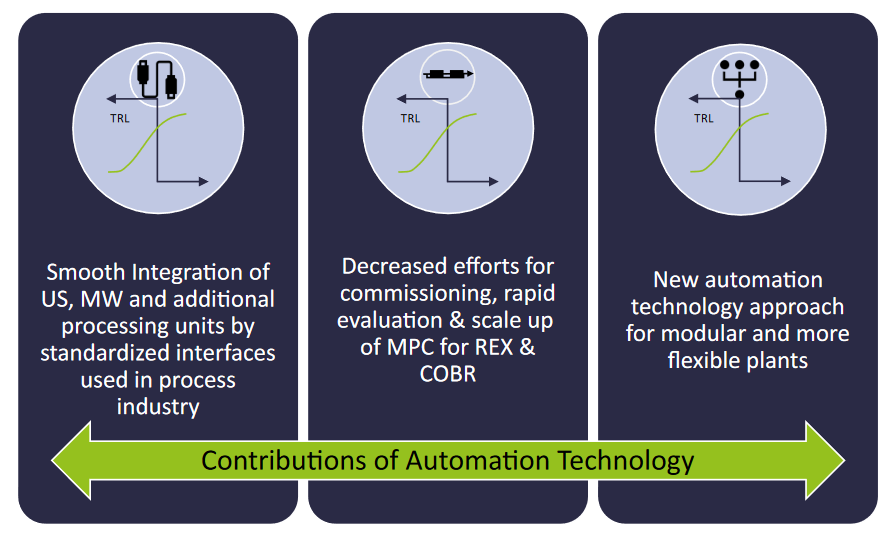

The aim of our work on process optimisation is to increase the Technology Readiness Level (TRL) of continuous processing of chemicals with high added value through innovative automation technologies. The contributions of automation technology serve to increase the flexibility for integration of the equipment in existing process control environments.

Our general approach can be transferred to different reactor types and products.

The modular model-based automatic operation of complex processes can deal with

- Nonlinear dynamics

- Several sensors and actuators, including alternative energy sources

- Flexible operation to adapt to varying product specifications or energy availability

- Important quality and safety constraints

- Optimal operation

General approach

The automation technology is modularized with an open, system-independent approach for modular systems in process industry

As part of our project work so far, LEIKON performed an analysis of both the reactive extruder 15mm pilot plant (location at Fraunhofer ICT) and COBR pilot plant (location at the end-user ARKEMA). Interfaces were identified from a plant automation perspective to create a common data integration layer with embedded APC and data historian.

TU Dortmund University has developed dynamic models of the reactive extruder pilot plant and the COBR pilot plant and is currently validating them. In addition, concepts for advanced model-based control were developed based on model predictive control (MPC) technology.

How do we proceed?

Status quo:

- pilot systems already developed in SIMPLIFY used non-digitised or separately digitised system modules without or with only system-specific interfaces

- comprehensive process data analyses and innovative process control approaches are time consuming or in the worst case not possible

Approach:

- developing a data hub & integration layer

- using/ developing standardized interfaces for all modules

Status quo:

- first MPC approaches developed in SIMPLIFY were evaluated offline

- improved MPC approaches already developed within SIMPLI-DEMO up to now also evaluated offline

Goal:

- support of rapid control scale up when scale up of plants

- MPC – going from offline evaluation to online use

- easy integration of MPC into industrial system environment

Approach:

- modular integration of MPC in integration layer

- introducing new upcoming standard of modular automation, called MTP (Modular Type Package)

Demand:

- the need of more modular and flexible plants results to the need of a modular automation technology

Leading partners